Conventional Services

Our conventional division offers a full array of e-line mechanical and logging services. Our highly trained managers and supervisors are equipped to handle all your completion and abandonment requirements.

Perforating and Mechanical Services

Our perforating and mechanical services can be wireline conveyed on vertical wells and on horizontal well applications via wireline pump down, wireline conveyed tractor tool or convey on jointed or coil tubing.

Services & Equipment:

- Tubing Conveyed Perforating (TCP) services include Percussion Activated, Ball Drop Activated, Pressure Activated Auto Release and Auto Venting Pressure Activated Firing Heads c/w TCP mechanical accessories including Separation Subs, Fill Flow Subs with Debris Barriers, Pressure Test Kobe subs, Ported Differential subs, Hydraulic Tubing Drain, Safety Impact Firing System, Tubing Swivels all of which can be deploy off of Jointed tubing or Coiled Tubing

- Perforating charge selections; Super Deep Penetrator (SDP), Good Hole (GH), Big Hole (BH), Consistent Hole Sizes (CHS) all of which can be configured in both tubing and casing guns with standard and or custom phasing and shot densities

- Channel finders and UZI guns, shot densities up to 118 spm

- Tubing and casing punch guns (designed to penetrate a single sting of pipe)

- Oriented perforating with gun decentralizes, swivels and indexing guns subs

- Debris magnets and gun centralizers

- Plug and perforating combo operations

- RF-safe detonators, RF-safe IP addressable switches, panels for select fire operations

- Setting bridge plugs, cement retainers, WR bridge plugs and packer assemblies (all sizes)

- Baker #5, #10, #20 and Multi Stage Setting tools cw/ standard and or slow set power charges

- Gauge ring junk basket (to fit all pipe sizes)

- Dump Bailers (for all pipe sizes) cw/ a full range of products from Sand, Class-G Cement, Hydromite, Chicken Grid and Hot-Set Cement for wells > 100°C

- Bailer activation method for vertical wellbore applications

- Explosive squibs for deviated wellbore applications

- Swabbing Services with limits on both depth and casing sizes

- Jet Cutters for both Casing and Tubing

- Kinley line cutters

Useful Links

Pressure Control Equipment (PCE)

Boreal Conventional E-Line has a full range of pressure control equipment (PCE) ranging from 7 MPa (1K Psi) to 103 MPa (15K Psi) allowing us to confidently service our customers no matter their pressure control needs.

We routinely update and certify our PCE to comply with stringent industry standards. Our team also maintains annual training and certificates necessary to properly operate the PCE safely and confidently during all e-line operations.

Services and Equipment

- Basic 7.0 MPa pack-off / lubricator / flange for 89 mm, 140 mm and 177.8 mm pipe sizes

- Basic Flange and Ring Gaskets- R- Series and BX-Series for High Pressure Wellhead connections

- Single Joints of Lubricator for 89 mm, 140 mm, 177.8 mm – 5K Psi / 34 MPa

- Single/Manual WL Control Valve 89 mm, 140 mm, 177.8 mm, Basic- 5K Psi / 34 MPa

- Single/Hydraulic WL Control Valve 89 mm. 140 mm, 177.8 mm, Basic – 5K Psi / 34 MPa

- Dual/Hydraulic WL Control Valve 140 mm, 177.8 mm, 10K psi

- BOP Accumulator Truck and Skid, Basic- 5K Psi / 34 MPa

- Head Catcher, Basic- 5K Psi / 34 MPa

- Tool Trap, Basic- 5K Psi / 34 MPa

- Environmental Line Stripper, Basic - 5K Psi / 34 MP

- Grease injector truck mounted and skid unit packages, Basic - 5K Psi / 34 MPa

- PCE Specialists

- Standard Oil, Synthetic Oil and Inhibitor

- N2 Pressure test and Purging equipment, Basic - 5K Psi / 34 MPa

- LEL monitors

Useful Links

Standard Logging Services

Our full complement of standard E-line logging tools can determine: cement bond, formation porosity, formation matrix, bed boundary delineation and casing collar identification. These tools are operated by our well-trained managers and supervisors, ensuring the data collected is accurate.

The retrieved data is transmitted to our expert team of log analysts and log processors in Calgary for further evaluation and interpretation. We also make sure to follow up with our customers to ensure complete comprehension of the results and make recommendations where required.

Services and Equipment

- Cement Bond Long

- Radial Bond Log

- Slim Hole Radial Bond log – 43mm OD

- Temperature Log

- Gamma Ray Correlation Log

- Gamma Gun Correlation Log

- Casing Collar Log

- Dual Spaced / Compensated Neutron Log

- Single Spaced Neutron Log

- Cement Plug Log (used for open hole abandonment applications)

Documents

Surface Casing Vent Flow (SCVF) and Gas Migration (GM) Logging Services

We understand the complex issues a surface casing vent flow (SCVF) or gas migration (GM) can pose for our customers when it comes to the final well abandonment. It is why we’ve committed significant resources over the past five years to solving these issues.

How? By building two specialized fiber-optic wireline units dedicated to running the HiFi MiCro Fiber Optic Directional Noise tool in combination with the Cased Hole Analysis Tool (CHAT) and Radial Cement Bondlog Tool (RBT).

With these tools at our disposal - combined with our highly-trained logging specialists and experienced team of log analysts- we confidently provide the answers required to re-solve these challenging SCVF and GM issues.

Services & Equipment

- Radial Cement Bond Tool (RBT): A RBT is primarily designed to evaluate the quality, quantity and bondability of cement to the pipe and formation. A good bond occurs when the cement is circumferentially bonded to both the casing and the formation. However, a poor bond occurs when there is a complete lack of cement, non-circumferential coverage around the casing (creating a channel), or there is a micro annulus to the pipe / the formation.

- Cased Hole Analysis Tool (CHAT) Log: The CHAT tool is a combination dual-energy neutron tool and a triple-detector density tool. The combined data can determine the presence of gas in both the annulus and the formation. It also provides specific reservoir characteristics such as formation lithology, porosity and or lack of porosity (tight formation). Learn more...

- MiCro/Temp – Fiber Optic Directional Acoustic Tool: The “MiCro Tool”- utilizes 2 High-Fidelity Fiber Optic Sensors to determine the loudness and phase amplitude of acoustic events located near the wellbore, the orientation of an acoustic event to the ABOVE or BELOW sensor determines the direction of flow and accurately pin points the depth of the acoustic source, the temperature log measures temperature fluctuations or trends to determine gas/liquid entry into the near wellbore annulus which helps locate potential source candidates.

- Standard Noise/Temp/Gamma Ray Tool combination: The Standard Noise tool utilizes a single geophone device to passively listen to changes in noise levels throughout a well bore. The noise is filtered into several frequencies and changes to these frequencies indicates potential liquid/gas sources. A frequency vs depth plot of the entire well also aids in identifying the approximate location of where the noise source originates.

Geo-Science Services

- Log Processing

- AER Submissions

- Lunch & Learn Presentations available upon request

Detailed interpretation summaries for the following logging services:

- Temp injection Surveys

- Casing inspection

- NT/MiCro/CHAT/RBT summary

- Production log Summary

Regulatory Compliance

Specialty Logging Services

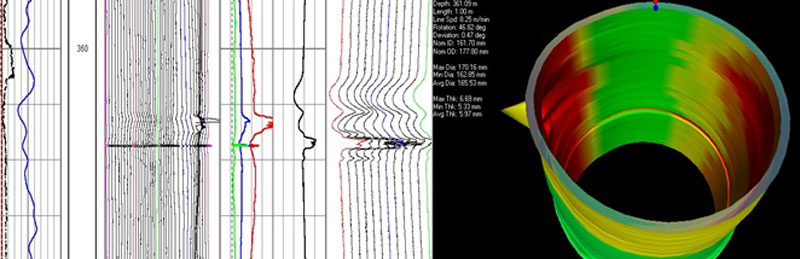

Specialty Well Integrity/Casing Inspection Logging Services

Our customers need immediate information regarding their tubing and casing issues. That’s why we use both GE/Sondex and GoWell technologies to help locate casing anomalies - from deformation and mechanical wear to corrosion monitoring.

Our customers need immediate information regarding their tubing and casing issues. That’s why we use both GE/Sondex and GoWell technologies to help locate casing anomalies - from deformation and mechanical wear to corrosion monitoring.

By using these casing inspection technologies, we have the unique ability to evaluate multiple strings of casing simultaneously, through a broad range of casing sizes from 60.3 mm to 473.1 mm. Our specialty supervisors receive custom training to use these technologies to ensure accurate and quality data is recorded on every casing inspection job.

Sondex/GE Casing Inspection Tools

- MIT (Multifinger Imaging Tool): Accurately measures internal casing wear, deformation and corrosion

- 24 Arm (50 mm - 178 mm measurement)

- 40 Arm (100 mm - 178 mm measurement with extensions up to 245 mm)

- 60 Arm (102 mm - 254 mm measurement)

- Can run in combination with the Magnetic Thickness Tool (MTT) to determine if casing anomalies are internal/external

- Capable of logging in real-time or memory mode

- Magnetic Thickness Tool (MTT): accurately measures pipe metal thickness

- Pipe dimensions from 54 mm - 178 mm

- Capable of logging in real-time or memory mode

Our Evaluation Software

- WIVA: enables the user to view the pipe in 3D to help understand the structure and condition of the well.

- WIPER: combines both the MIT and MTT data into a joint-by-joint statistical analysis and builds a report summarizing the condition of the pipe in the wellbore.

Documents

Useful Links

GoWell Logging Tools

- Multi Finger Caliper (MFC): accurately measures internal casing wear, deformation and corrosion

- 56 arm (102 mm - 254 mm measurement)

- Built-in wellbore temperature and 3-axis accelerometer to provide crucial information about temperature, deviation and finger position

- Can run combination with Magnetic Thickness Detector (MTD)

- Capable of logging in real-time or memory mode

- Magnetic Thickness Detector (MTD): can quantitatively evaluate up to three strings of pipe up to 473.1 mm

- Primarily run through tubing with the capability to simultaneously inspect concentric strings of pipe behind the tubing

- Reduces costs in routine casing integrity logging, as tubing does not have to be pulled for accurate information

- Fast logging speeds for single pipe evaluation

- Chrome / alloy pipe evaluation

- Capable of logging in real-time or memory mode

- Analysis Software: GoWell has a 24/7 Well Integrity Service Team that processes and evaluates the data into a customized report of the entire well bore up to three strings of casing.

Production Logging Services

We understand that our customers require immediate information regarding reservoir performance data in a single run. That’s why we’ve chosen a comprehensive suite of GE/Sondex and and Lee-DataCan production logging tools: so we can economically evaluate and accurately measure key production parameters such as temperature, flow (spinners), capacitance, fluid identification (density) and pressure measurements.

Along with these key reservoir measurements, we work closely with our customers to design production logging programs to optimize and obtain accurate results specific to their logging needs.Upon completion of the logging program, a detailed evaluation of the data is formatted into a final report.

Services and Equipment

- 43 mm OD tool string

- Capable of logging in Real Time (E-line, Smart Coil) or Memory Mode (E-line, Slickline or Coil Tubing)

- Sweet and sour well environments

- Vertical, highly-deviated and horizontal applications

- Temperature – used to identify borehole fluid temperature which can be used for finding fluid entry, gas leaks, and injection or storage zones

- Flowmeter both Fullbore and Inline Spinners – the selection of flow meter is determined by several wellbore parameters such as pipe size, expected fluid phase, flow rate and quantity of debris in the flow

- Capacitance Water Hold-up – measures the dielectric constant of surrounding borehole fluid to determine water hold-up, can determine down hole hydrocarbon/water ratio

- Fluid Density – uses low energy gamma rays to evaluate down hole fluid density – excellent for horizontal wells

- Quartz Pressure – used to monitor continuous borehole fluid pressure, good for draw down and pressure build up flow tests

- Telemetry Tool for Real Time logging applications

- Memory Logging system – battery powered memory system controls the logging tools and stores data, depth is recorded against time and then all data is merged to create a standard API PL log

- Additional PL tools; Gamma Ray, CCL , Roller Centralizers, Bow Spring Centralizers, Knuckle Joints, Swivel Joints and Tungsten Weight bars